Ideal Info About How To Build An Engine Dyno

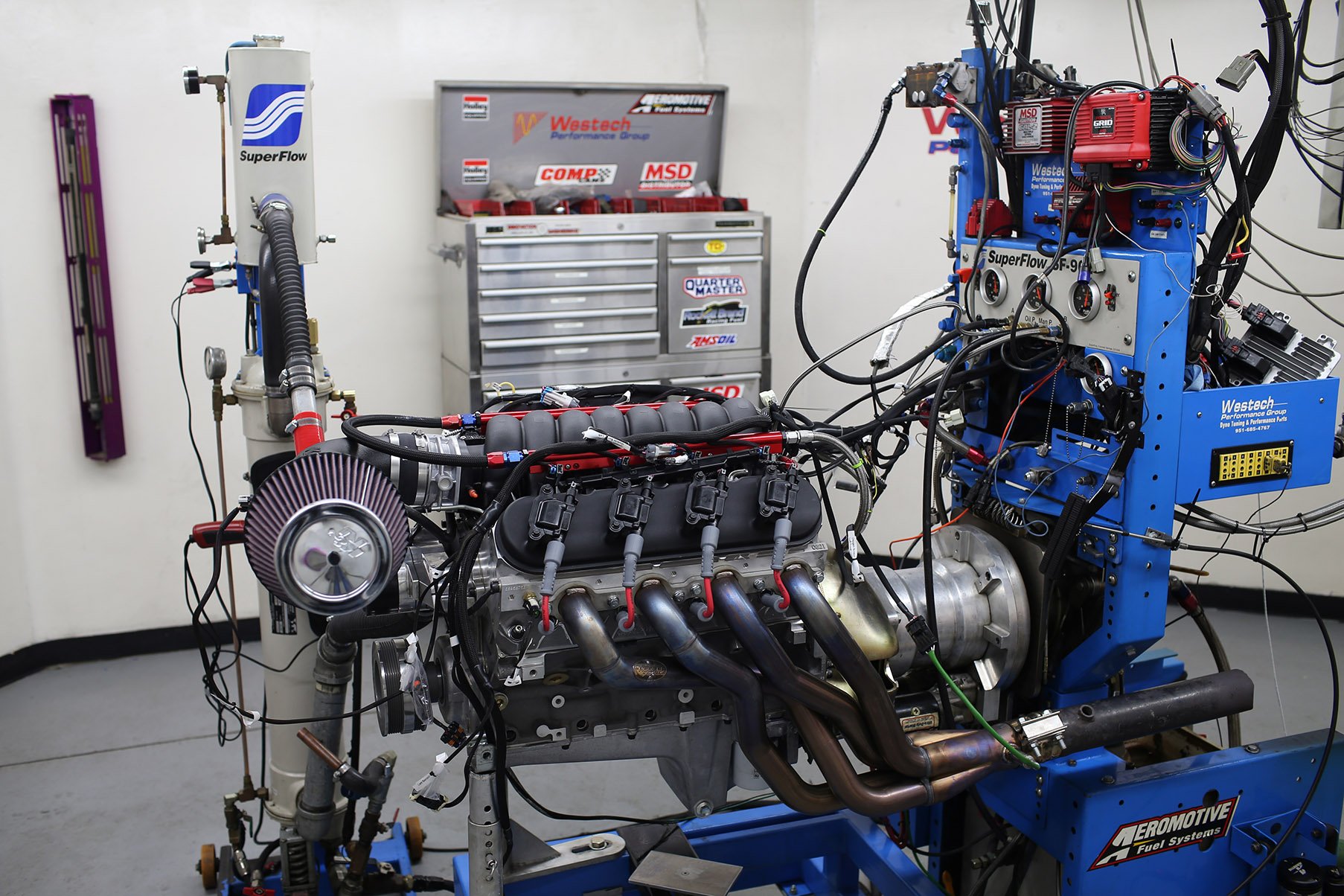

It’s built on the same platform that gm uses for their nascar program.

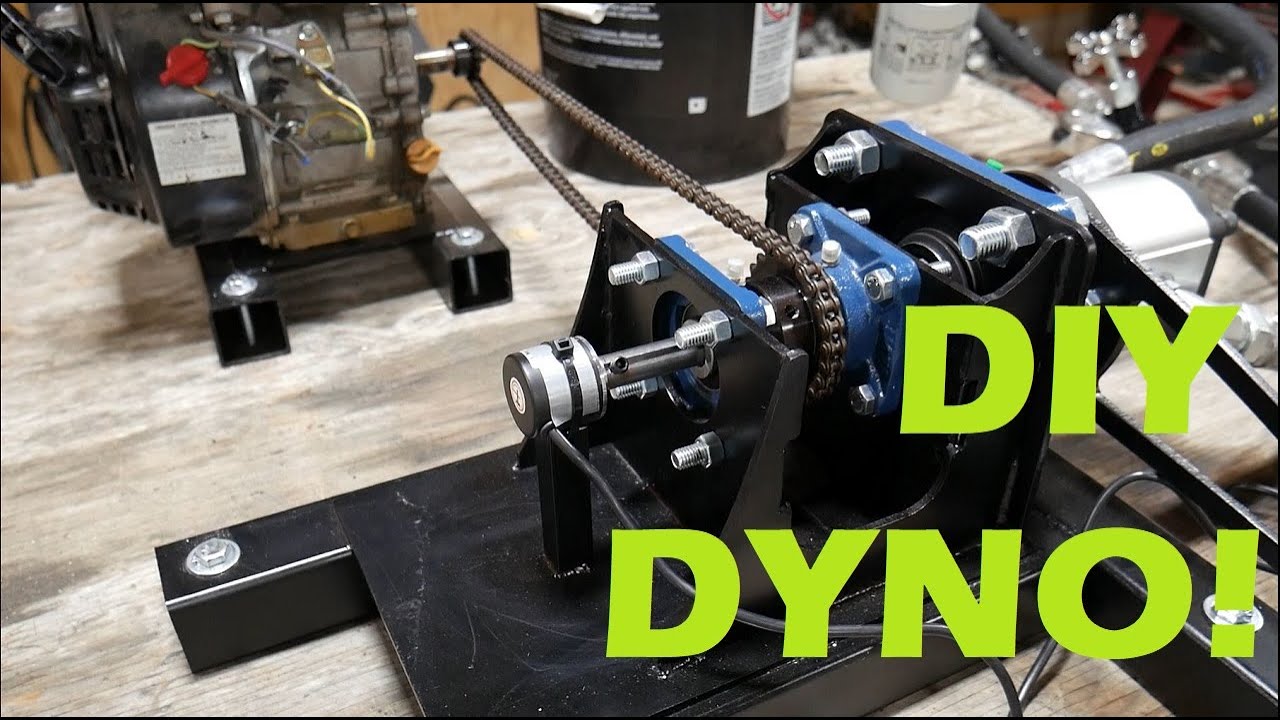

How to build an engine dyno. So basically i’m cheap, and want to tune engines. The frame is made from 75x75x6 box section and will be eventually bolted to the floor. How to prepare foran engine dyno.

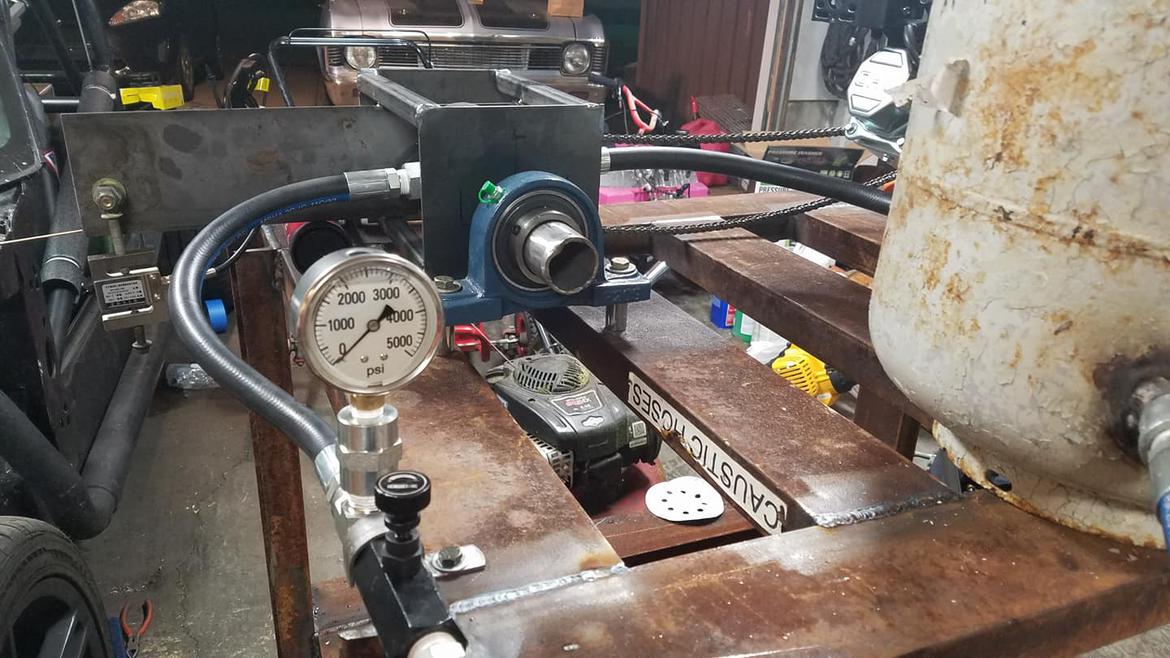

Our engine dyno was built for superior performance. Building a water brake engine dyno, or how i learned to love math. Some water brake and hydraulic dynamometers cost $3,000 to $8,000 used.

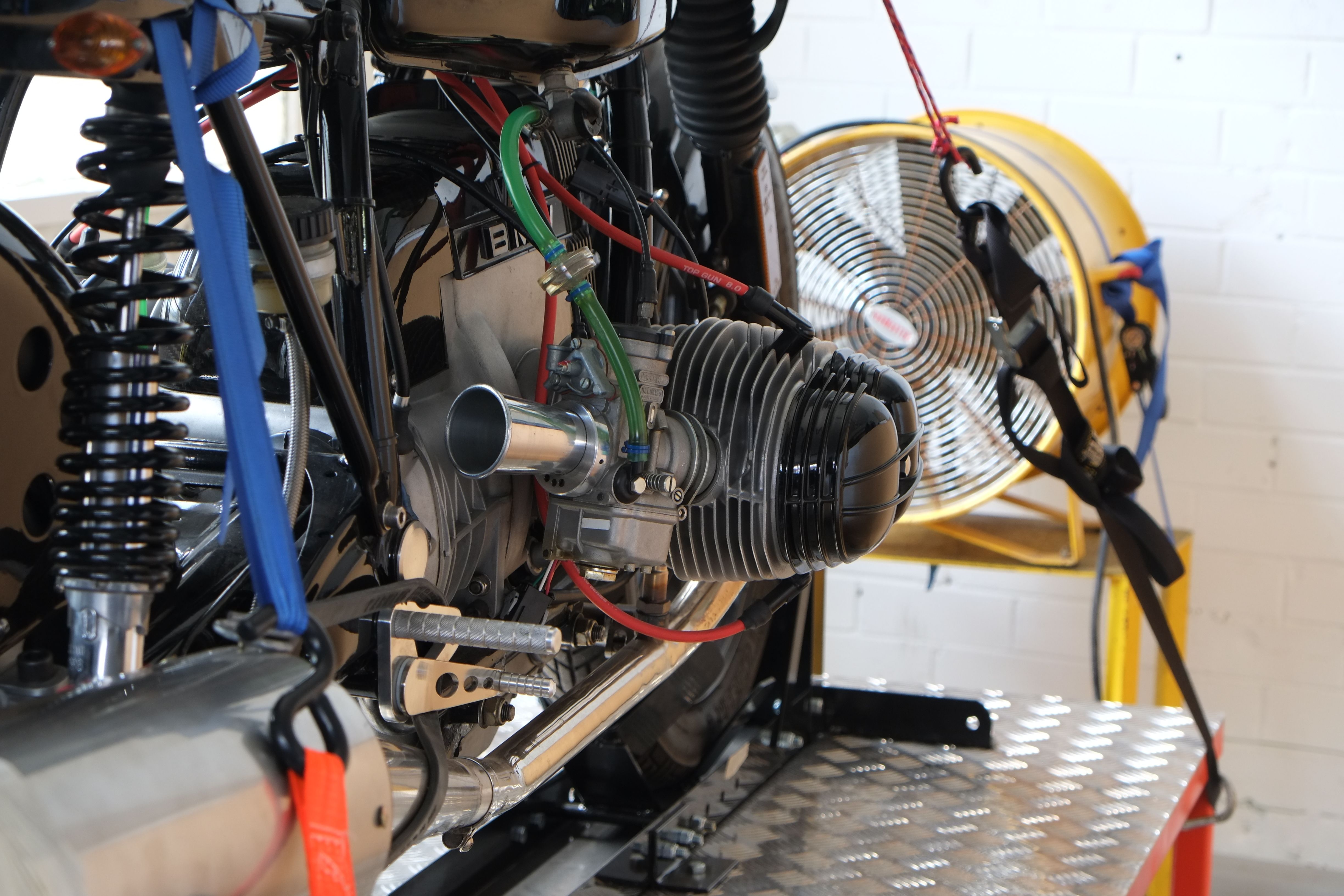

The first technique we can use on the dyno is called steady state operation. Thanks to the smaller 64cc combustion chambers, compression. How to chose a dyno testing facility, what is involved in the process, how long does it take, what problems you can run intoautomotive engines diagnosis repa.

After installing fresh head gaskets, engine owner dale snoke installed the aluminum heads on the 383. At its heart is a go power dual. And this is where we set the dyno to hold a constant engine rpm, or road speed in the case of a chassis.

The cost may seem steep at first (usually anywhere from $500 to $1,000 for a day's worth of dyno time), but the value comes from knowing exactly how much power your engine. As a side note, now is the time to introduce the idea of , which is work times. The simplest way to diy a dyno for car type engines (i'm guessing this is you intent) is to take an eddy current brake, think telma, frenelsa etc, mount it to a sturdy frame with a.